Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

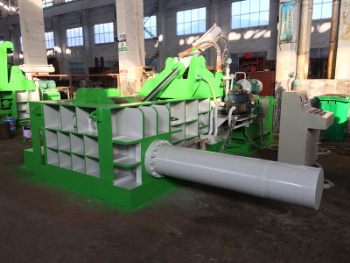

Efficient Metal Baler for Leftover Steel, Paring Waste, Copper, and Aluminum

Model No.: Y81T-250

Brand: Ecohydraulic

Place Of Origin: China

Status: New

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Warranty Period: 1 Year

Machinable Material: Brass / Copper, Alloy, Aluminum, Carbon Steel, Stainless Steel

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Warranty: One Year

Quality: Iso9001:2008

Color: As Your Require

Cooler: Water Cooler/Air Chiller

Operation: Manual/Plc Automatic

Packing: Nude Packing

Press Force: 2500kn(250ton)

Bale Size: 400*400mm Or 500*500mm

Power: 22kw*2 Or 30kw*2

Shipment: 40hc Or 40ot

Packaging: nude packing

Productivity: 30 Sets/Month

Transportation: Ocean

Place of Origin: Jiangsu, china

Supply Ability: 30 Sets/Month

Certificate: ISO, CE, SGS,TUV

HS Code: 8462919000

Port: Shanghai

Payment Type: T/T

Incoterm: FOB,CFR,CIF,EXW

Introducing our Metal Leftover Steel Paring Waste Copper Aluminum Baler, designed exclusively for professionals seeking efficient waste management solutions. This robust and high-performing baler is engineered to streamline the process of compacting and recycling metal leftovers, steel parings, waste copper, and aluminum. With its advanced technology and precision engineering, this baler ensures optimal compression, reducing the volume of waste materials and maximizing storage space. Its user-friendly interface and automated functions make it easy to operate, saving valuable time and effort. Invest in our Metal Leftover Steel Paring Waste Copper Aluminum Baler to enhance your waste management practices and contribute to a greener environment.

Metal Leftover Steel Paring Waste Copper Aluminum Baler can squeeze scrap metals into cuboid, cylinder and other various shapes, its compression ratio is high, convenient for storage, transportation and smelting, it improves the furnace feeding efficiency, suitable for scrap steel processing and distribution center, scrap car dismantling center, casting industry, steel mills and non-ferrous metal industry.

All kinds of metal scraps, waste steel, copper, aluminum shavings, car shells, etc., is produced every day of production, our hydraulic metal baler can compress every kinds of metal leftover materials into qualified charging such as square, cylinder, octagon body and other shaps.

This machine reduce your cost of transporation and smelting.

| model | Y81T-250A | Y81T-250B | Y81T-250C |

| nominal force | 2500kn | 2500kn | 2500kn |

| press box size | 2000*1400*900mm | 2000*1750*1000mm | 2500*2000*1200mm |

| bale size | 500*500mm/600*600mm | 500*500mm/600*600mm | 500*500mm/600*600mm |

| bale weight | 180~300kg | 200~350kg | 210~360kg |

| production | 20~36t/8h | 30~40t/8h | 32~42t/8h |

| total power | 22kw*2 | 30kw*2 | 30kw*2 |

| machine weight | about 19ton | about 23ton | about 27ton |

Product Categories : Baling Machine > Steel Baler

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.