Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

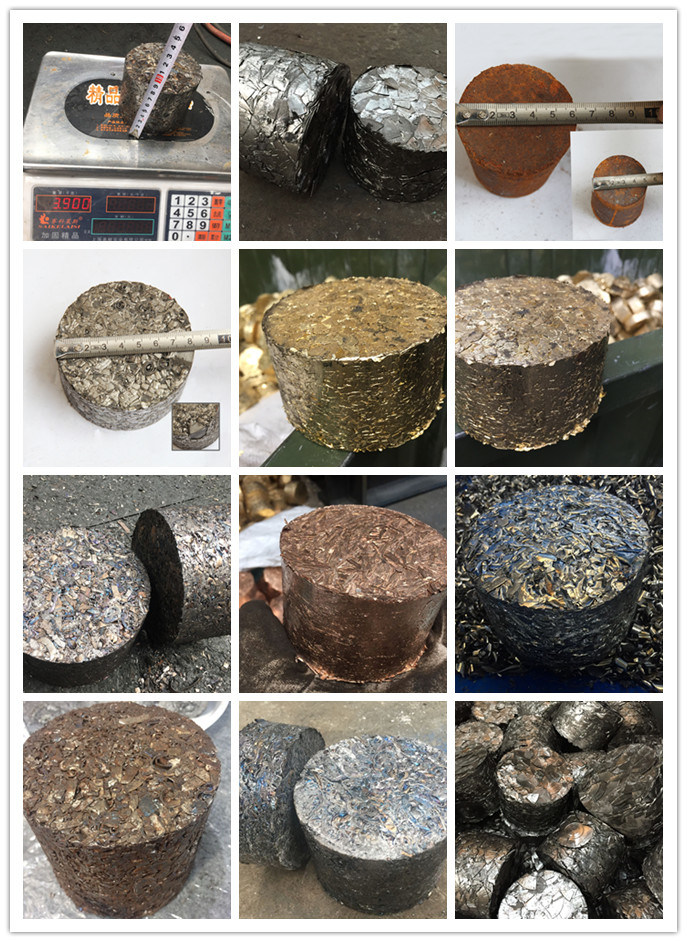

"Efficient and Versatile Machinery for Processing Steel Granules, Iron Turnings, and Copper Briquettes: A Must-Have for Professionals in the Metal Recycling Industry"

Model No.: Y83W-2000

Brand: Zhouzhuang

Place Of Origin: China

Status: New

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Ordinary Product

Core Component Warranty Period: 1 Year

Warranty Period: 1 Year

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Operation: Siemens Plc Automatic

Cooler: Water Cooler

Color: As Your Require

Quality: Iso9001: 2008

System Working Pressure: 25mpa

Press Force: 20000kn (2000ton)

Briquette Density: About 4500kg/M3

Briquette Size: D410*380~410

Total Power: 600kw

Output: About 32t/H

Packaging: nude packing

Productivity: 30 Sets/Month

Transportation: Ocean,Land

Place of Origin: Jiangsu, China

Supply Ability: 5 Sets/Month

Certificate: ISO9001:2008/CE

HS Code: 8462919000

Port: Shanghai

Payment Type: T/T

Incoterm: FOB,CFR,CIF,EXW

Introducing the "Metal Master 3000" - the ultimate solution for transforming steel granules, iron turnings, and copper into briquettes of pure awesomeness! This incredible machine is like a magician's hat, turning scrap metal into shiny treasures with just a flick of a switch. Say goodbye to dull and lifeless metal waste, and hello to compact and stylish briquettes that will make even your boss's jaw drop! Not only will the "Metal Master 3000" save you time and money, but it will also make you the coolest metal enthusiast in town. Get ready to briquette and roll like a boss!

Copper briquetter brings optimized storage and more efficient transport through volume reduction as well as cost-effective further processing. The briquetting process for metals also enables the recovery of expensive cooling lubricants, residual oils and emulsions, which are then fed back into the cooling or lubrication circuit. The resulting metal briquettes can be melted down directly, whereby they sink down in the melting process and thus melt with less slag formation and burn-off.

1. Application and features for horizontal Briquette Machine

| model | Y83W-2000 |

| nominal force | 20000kn |

| briquette diameter | D410 |

| briquette density | about 4.5t/m³ |

| briquette weight | 180~200kg |

| productivity | 3block/min |

| output in one shift | about32t/h |

| total power | 90kw*7 |

| |

Product Categories : Briquette Machine > Horizontal Briquette Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.